Imagine this—you're working on a project that demands precision, flexibility, and cutting-edge technology. Enter the 12 ft. servo skelly, the game-changer in automation and robotics. Whether you're an engineer, hobbyist, or tech enthusiast, this guide will give you everything you need to know about 12 ft. servo skelly and why it’s a must-have for your next big project. So, buckle up and let's dive in!

Now, before we get into the nitty-gritty, let's set the stage. The world of automation is evolving at lightning speed, and the 12 ft. servo skelly is right at the heart of it. It's not just a piece of equipment; it's a symbol of innovation and efficiency. If you're thinking about integrating this into your workflow, you're in the right place.

This article is designed to take you from zero to hero in understanding 12 ft. servo skelly. We'll cover everything from its history, how it works, to the best practices for implementation. So, whether you're looking to upgrade your machinery or simply curious about what all the fuss is about, we've got you covered. Let's get started!

- Nelly Furtado Curvy The Iconic Voice Behind The Curves

- Who Is Rachel Dunn Unveiling The Fascinating Story Behind The Iconic Figure

Table of Contents

- What is 12 Ft. Servo Skelly?

- A Brief History of Servo Skelly

- How Does 12 Ft. Servo Skelly Work?

- Applications of 12 Ft. Servo Skelly

- Benefits of Using 12 Ft. Servo Skelly

- How to Choose the Right 12 Ft. Servo Skelly

- Maintenance Tips for 12 Ft. Servo Skelly

- Common Issues and Troubleshooting

- The Future of 12 Ft. Servo Skelly

- Conclusion

What is 12 Ft. Servo Skelly?

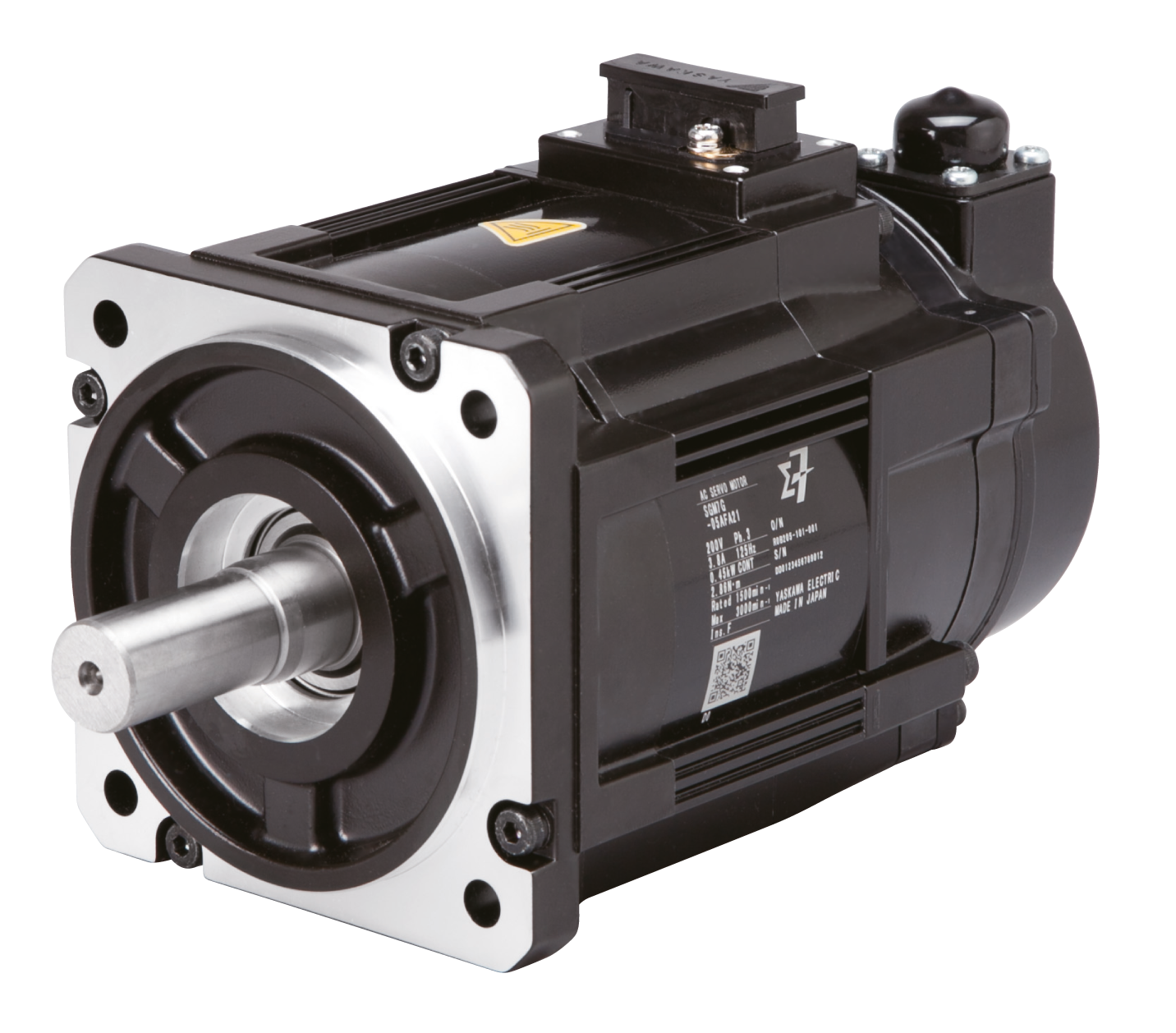

Alright, let's break it down. A 12 ft. servo skelly is essentially a type of robotic arm designed for heavy-duty tasks. It's equipped with advanced servomotors that allow for precise movements and unmatched control. Think of it as the Swiss Army knife of automation—versatile, powerful, and reliable.

Now, what makes the 12 ft. version so special? Well, its size gives it an edge in handling larger projects without compromising on accuracy. Whether you're assembling cars or building skyscrapers, this beast can handle it all. It's like having a personal assistant that never gets tired and always gets the job done right.

But wait, there's more! The 12 ft. servo skelly isn't just about size; it's about precision too. Its ability to execute complex movements with pinpoint accuracy is what sets it apart from other robotic systems. So, if you're looking for something that can keep up with your demands, this is it.

- Does Marlo Thomas Have Cancer Unveiling The Truth Behind The Rumors

- Top Gifts For A 60 Year Old Man Celebrating Life Style And Adventure

A Brief History of Servo Skelly

Let's rewind a bit and take a look at where it all began. The concept of servo-controlled machinery dates back to the early 20th century, but it wasn't until the 1960s that servo skelly started gaining traction. Back then, it was mainly used in manufacturing plants for repetitive tasks.

Fast forward to today, and the 12 ft. servo skelly has evolved into a powerhouse of innovation. Advances in technology have made it smarter, faster, and more efficient. Companies across the globe are now leveraging its capabilities to streamline operations and boost productivity.

Key Milestones in Servo Skelly Development

- 1960s: First servo-controlled machines introduced

- 1980s: Integration of microprocessors for enhanced control

- 2000s: Development of larger, more powerful models like the 12 ft. servo skelly

- 2020s: Focus on AI-driven automation and IoT integration

How Does 12 Ft. Servo Skelly Work?

Alright, let's get technical for a moment. At its core, the 12 ft. servo skelly operates on a simple principle: feedback control. Here's how it works—there's a motor that powers the movement, and sensors constantly monitor its position and speed. This data is then fed back to a controller, which adjusts the motor's output to ensure precision.

But that's not all. Modern 12 ft. servo skelly systems are equipped with advanced algorithms that allow for real-time adjustments. This means it can adapt to changing conditions on the fly, making it perfect for dynamic environments. It's like having a brain that can think and react in milliseconds.

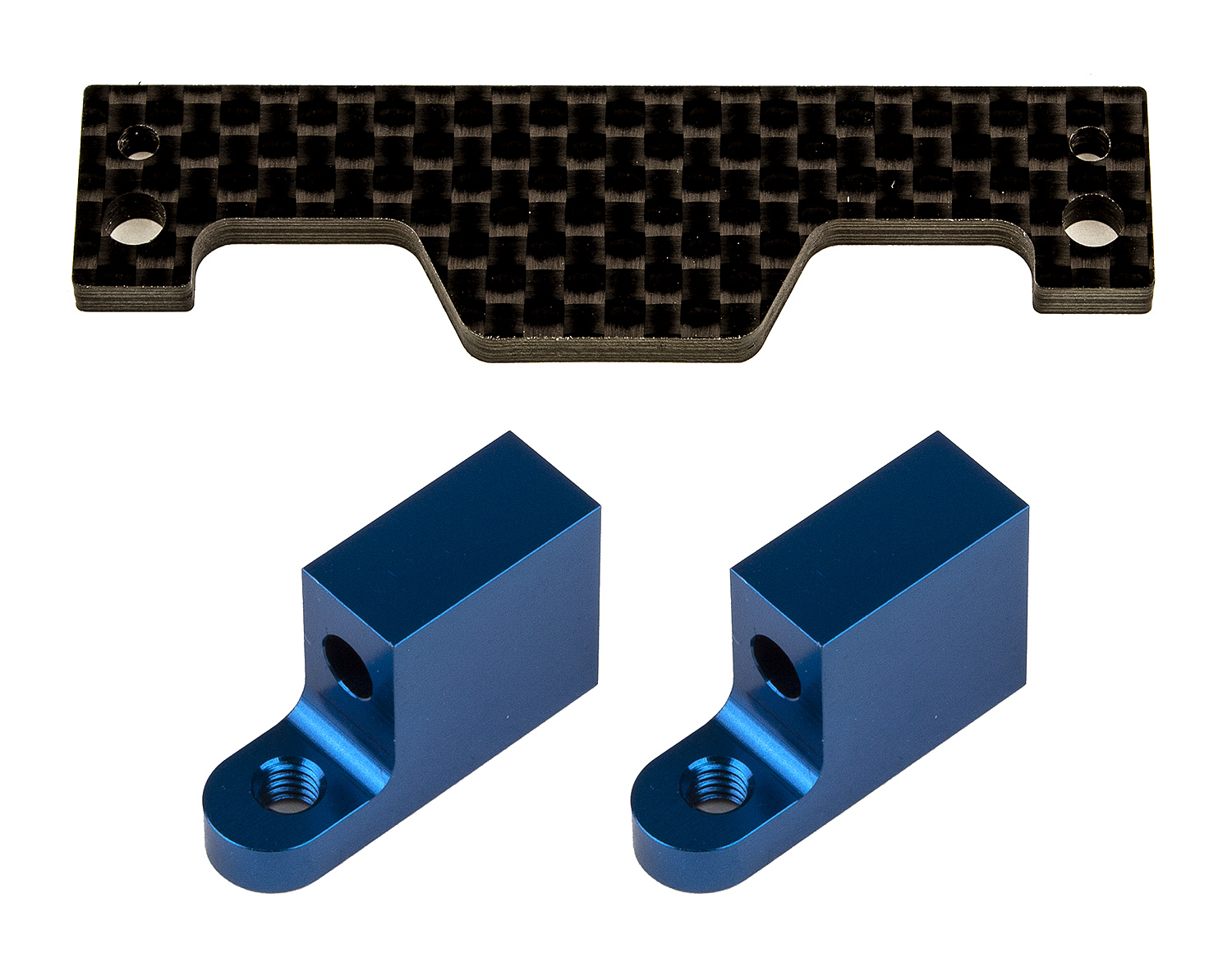

Key Components of 12 Ft. Servo Skelly

- Servomotor: The heart of the system, providing power and control

- Encoder: The eyes and ears, providing feedback on position and speed

- Controller: The brain, processing data and making decisions

- Actuator: The muscles, executing movements based on commands

Applications of 12 Ft. Servo Skelly

Now that we know how it works, let's talk about what it can do. The applications of 12 ft. servo skelly are virtually limitless. From manufacturing to construction, it's making waves in every industry. Here are just a few examples:

In manufacturing, it's used for assembly lines, packaging, and quality control. In construction, it's perfect for lifting heavy materials and performing intricate tasks. Even in healthcare, it's being used for surgical procedures and patient care. It's like a jack-of-all-trades that can adapt to any situation.

Industries Benefiting from 12 Ft. Servo Skelly

- Automotive: Assembly lines and component manufacturing

- Construction: Lifting and positioning heavy materials

- Healthcare: Surgical robots and patient assistance

- Logistics: Warehousing and inventory management

Benefits of Using 12 Ft. Servo Skelly

So, why should you consider investing in a 12 ft. servo skelly? The benefits are clear. First and foremost, it offers unmatched precision. Whether you're dealing with delicate components or heavy machinery, it can handle it all with ease.

Then there's the issue of efficiency. With its ability to work around the clock without fatigue, it can significantly boost your productivity. Plus, it reduces the risk of human error, ensuring consistent quality in every project. It's like having a superhero on your team that never takes a break.

How to Choose the Right 12 Ft. Servo Skelly

Alright, so you're convinced, but how do you choose the right one for your needs? There are a few key factors to consider. First, think about the size and weight of the objects you'll be handling. A larger model might be necessary for heavier tasks, while a smaller one could suffice for lighter duties.

Next, consider the level of precision required. Some models offer more advanced features than others, so it's important to match the specs to your specific needs. And don't forget about budget—while investing in quality is important, you also want to make sure it fits within your financial constraints.

Key Considerations When Choosing a Servo Skelly

- Load capacity: Ensure it can handle the weight of your tasks

- Precision: Match the accuracy to your project requirements

- Features: Look for advanced options like AI integration

- Budget: Find a balance between cost and quality

Maintenance Tips for 12 Ft. Servo Skelly

Now, let's talk about keeping your 12 ft. servo skelly in top shape. Regular maintenance is crucial to ensure it continues to perform at its best. Start by scheduling routine inspections to catch any potential issues early on. This could include checking for wear and tear, lubricating moving parts, and calibrating sensors.

Additionally, make sure to follow the manufacturer's guidelines for maintenance. This will help extend the lifespan of your equipment and prevent costly repairs down the line. It's like taking your car in for an oil change—it might seem like a hassle, but it's worth it in the long run.

Common Issues and Troubleshooting

Even the best equipment can run into problems from time to time. Here are a few common issues you might encounter with your 12 ft. servo skelly and how to fix them:

- Motor Overheating: Check for proper ventilation and ensure the load isn't too heavy

- Positioning Errors: Calibrate the encoder and verify sensor accuracy

- Sluggish Movement: Inspect for mechanical blockages and lubricate moving parts

Remember, prevention is key. By addressing issues early and performing regular maintenance, you can avoid many headaches down the road.

The Future of 12 Ft. Servo Skelly

Looking ahead, the future of 12 ft. servo skelly is bright. Advances in AI and IoT are paving the way for even smarter and more connected systems. Imagine a world where your servo skelly can predict maintenance needs before they arise or communicate seamlessly with other machines in your facility.

Additionally, there's a growing focus on sustainability. Manufacturers are developing more energy-efficient models that not only save costs but also reduce the environmental impact. It's like having a machine that's not only powerful but also eco-friendly.

Conclusion

In conclusion, the 12 ft. servo skelly is a game-changer in the world of automation. Its precision, versatility, and efficiency make it an invaluable asset for any project. Whether you're a seasoned engineer or a tech enthusiast, there's no denying its potential to transform the way we work.

So, what are you waiting for? Dive into the world of 12 ft. servo skelly and see the difference it can make. And don't forget to share your thoughts in the comments below or check out our other articles for more insights. Together, let's build a smarter, more efficient future!

- Whatrsquos The Deal With Smothers Theater A Deep Dive Into The World Of Comedy And Drama

- Michael Mcdermott The Untold Story Of A Gaming Legend